Incabloc: The Shock Protection System in Mechanical Watches

Discover Incabloc, the revolutionary shock protection system in mechanical watches. Learn how it works, its history, and why it’s essential for durability.

In the world of mechanical watches, precision engineering meets artistry. One of the most critical innovations ensuring the longevity of these timepieces is the Incabloc shock protection system. Developed in the 1930s, this technology revolutionized watchmaking by safeguarding delicate movements from impacts. Here’s an in-depth look at how Incabloc works and why it remains a cornerstone of mechanical watch durability.

What Is Incabloc?

Incabloc is a shock absorption system designed to protect the balance wheel and its pivots—the most fragile parts of a mechanical movement—from damage caused by sudden impacts. Invented by Swiss engineers Georges Braunschweig and Fritz Marti in 1934, it became the industry standard for shock resistance.

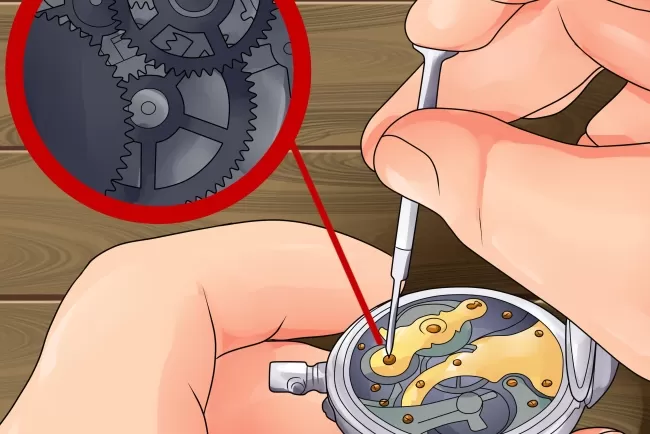

How Does Incabloc Work?

The system relies on a spring-mounted jewel bearing that allows the balance staff to flex slightly upon impact, redirecting stress away from the pivots. Key components include:

- Balance Staff Pivots: Tiny axles that rotate the balance wheel.

- Shock Absorbing Springs: Flexible metal springs that cushion the jewel bearings.

- Conical Endstones: Hardened jewels that absorb and redistribute force.

When a watch suffers a blow, the springs temporarily displace the jewels, preventing the pivots from snapping. Once the force dissipates, the system returns to its original position.

The History of Incabloc

Before Incabloc, mechanical watches were highly susceptible to damage from drops or bumps. The invention addressed a major pain point for watchmakers and wearers alike. By the 1950s, Incabloc was adopted by major Swiss brands like Omega, Longines, and Tissot, cementing its reputation as a reliability benchmark.

Incabloc vs. Other Shock Systems

While Incabloc dominates, alternatives like Kif (used by Patek Philippe) and Etachron (Seiko’s proprietary system) offer similar protection. However, Incabloc’s advantages include:

- Standardization: Widely used across entry-level to luxury watches.

- Ease of Repair: Watchmakers are familiar with its design.

- Proven Durability: Over 80 years of real-world testing.

Why Is Shock Protection Important?

Mechanical watches operate at high frequencies (e.g., 28,800 vibrations per hour). Without shock absorption:

- Pivot Breakage: Even minor impacts can snap balance staff pivots.

- Timekeeping Errors: Misalignment disrupts the escapement’s accuracy.

- Costly Repairs: Replacing a balance wheel is labor-intensive.

Incabloc mitigates these risks, extending a watch’s lifespan.

Modern Applications

Today, Incabloc is found in everything from vintage Rolexes to affordable ETA-powered watches. High-end brands may use proprietary systems, but Incabloc remains the go-to for accessible reliability.

What's Your Reaction?